RDCAM is a high performance control system embedded in laser machines, EAGLECAM is a customized version of RDCAM which support our premium EaglePrint print driver software.

The control card has a configuration profile stored in it according to the laser machine equipped with, to support the specific machine setup. Sometimes, you need to program the card corresponding to setup changes of the laser machine, like replacing a new control card, changing space between dual laser heads, temporarily disabling door sensor protection, etc..

We’ll guide you through the programming progress in EagleWorks (for EAGLECAM, almost same progress in RDWorks for RDCAM) in this document step by step.

Table of Contents

Programming Vendor Settings

The control card has a set of settings, protected by a password, generally programmed by laser machine manufactories, which is called vendor settings. But sometimes, you need to do that by yourself, especially for sales agency.

Please refer to sections below according to your specific needs.

Before starting

The laser machine needs to be powered on and connected with the computer which has EagleWorks installed on it. Open EagleWorks and follow steps below.

Read settings failed with "No Conected Device!" message?

If the laser machine is already powered on and connected with the computer, then there should be something wrong with the physical connection or connection settings in EagleWorks.

I Want to Program A New Control Card

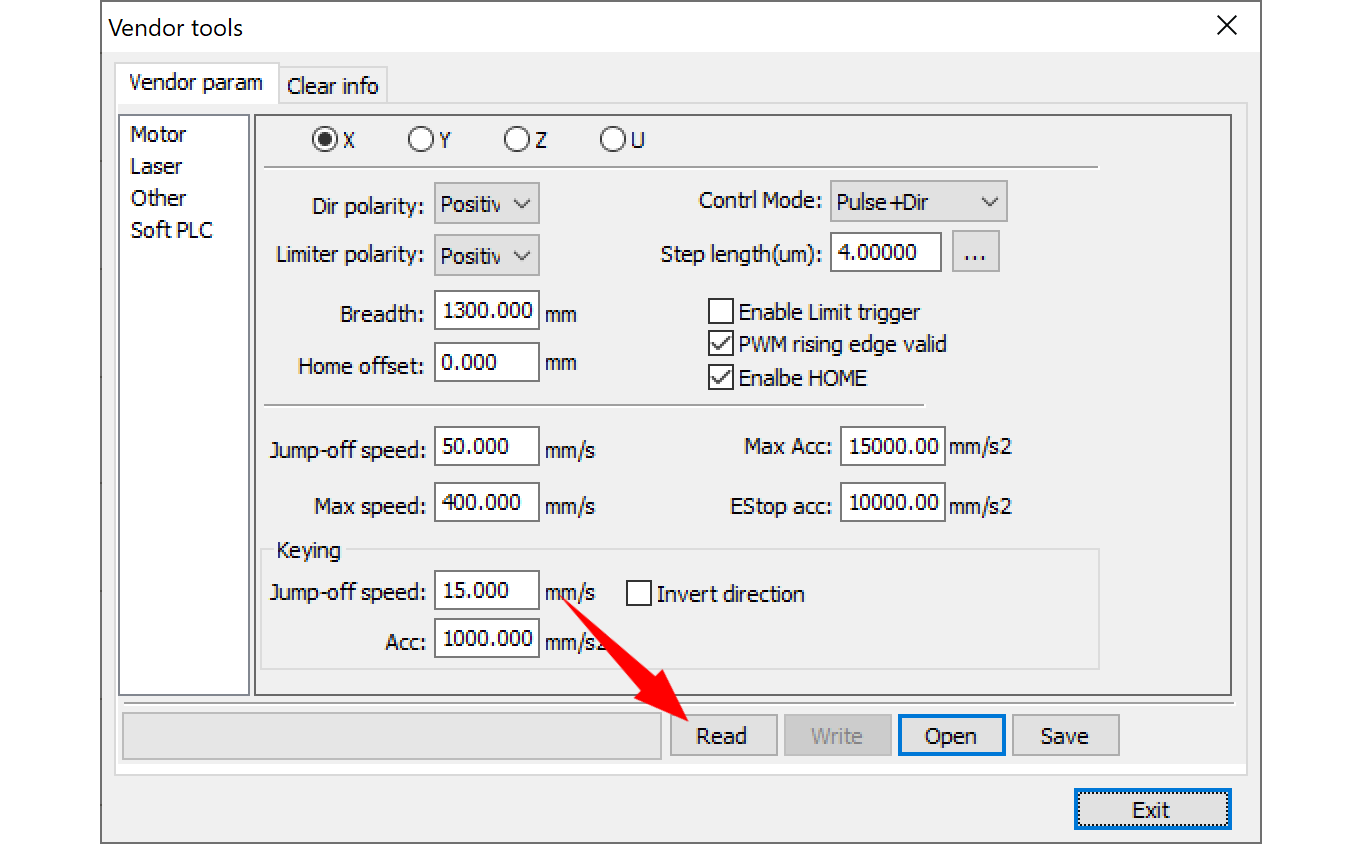

- Open vendor settings dialog – Click on File -> Vendor settings menu item, you’ll see the Vendor Parameter Password dialog shown as below. Input “rd8888” as password, click on OK button, then you’ll see the vendor settings dialog.

- Read settings from the laser machine – Click on Read button to get settings from the laser machine first.

IMPORTANT: Don’t forget to do this step first, otherwise, the Write button will not be activated.

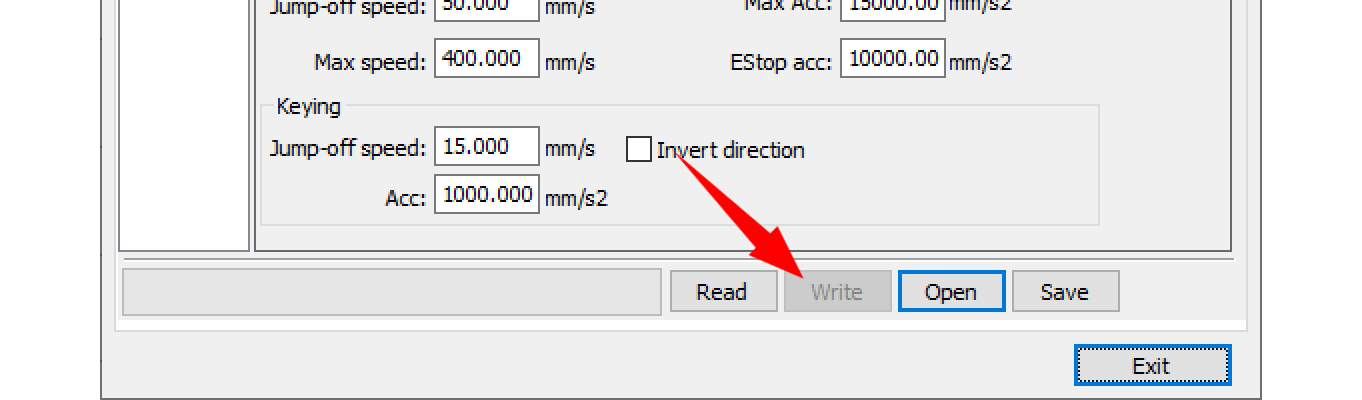

IMPORTANT: Don’t forget to do this step first, otherwise, the Write button will not be activated. - Import the configuration profile – Click on Open button to import the configuration profile. It will overwrite current settings in the dialog.

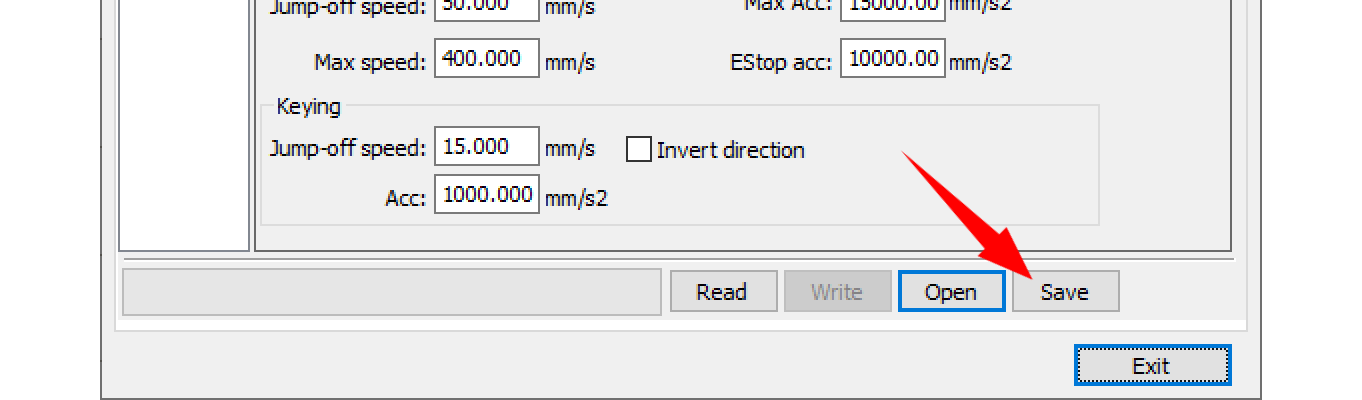

TIPS: Click on Save button to back up current settings to a file. Having a backup file is always a good practice, especially when you update control card after a mess.

TIPS: Click on Save button to back up current settings to a file. Having a backup file is always a good practice, especially when you update control card after a mess. - Write settings to the laser machine – Click on Write button to send settings to the laser machine.

- Restart the laser machine to finish programming – Some settings will be effective after restart. Please keep a hand on the emergency button to guard against any unexpected situation after programming.

I Want to Change A Specific Option

Before starting, please check the corresponding technical reference to your case carefully, or contact us about your specific needs, to confirm which option(s) to change.

Always Backup Current Settings

Always click the Save button in vendor settings dialog to back up the current settings, before making any changes.

- Open vendor settings dialog and read settings from the laser machine – Same steps as in the previous section.

- Back up current settings – Click on Save button to back up current settings, which can be used to restore the laser machine from a mess.

- Change the option(s) – Change settings according to your needs. Uncheck the Enable protect option here for example, to disable door sensor protection.

- Write settings to the laser machine and restart to finish programming – Same steps as in the previous section.

- Test if the laser machine behaves like what you expected – Check if the changes take effects. If there’s anything wrong, check out the technical reference or contact us for support. Or follow steps in previous section to restore the original settings if you want.

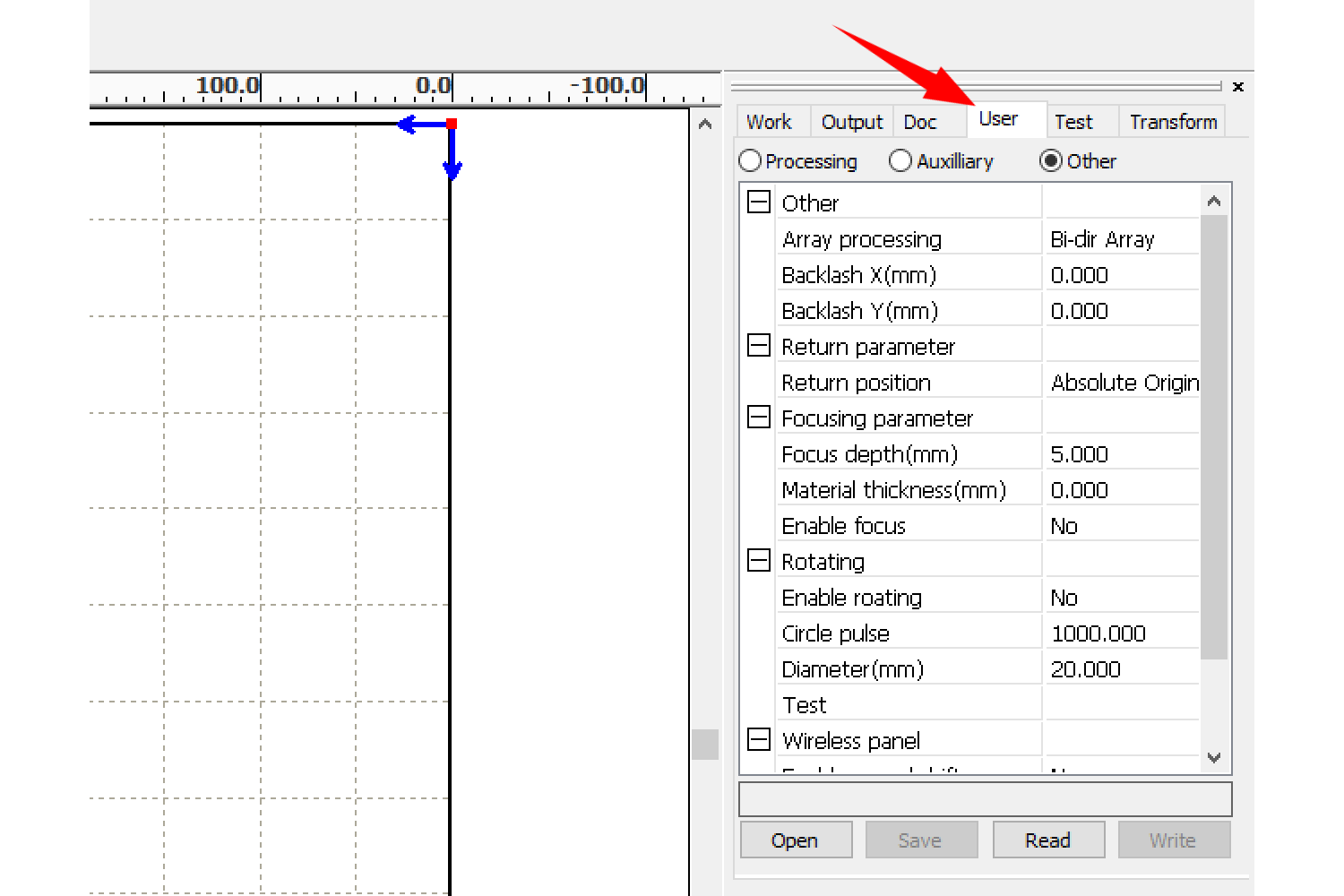

Programming User Settings

User settings, as the name revealed, are for changing some behaviors of the laser machine in daily use by the user, like changing return position after working, enabling rotary system, etc.. You can check them out in the User pane on right side of EagleWorks.

- Read settings from the laser machine – Click on Read button to get settings from the laser machine first.

- Change the option(s) – Change settings according to your needs. Change Return position to None here for example, to let the laser head stop at where it is after working.

- Write settings to the laser machine – Click on Write button to send settings to the laser machine.

- Restart the laser machine to finish programming – Some settings will be effective after restart. Please keep a hand on the emergency button to guard against any unexpected situation after programming.